Many people ask the question “How do you make solar panels?”. Solar panels consist of an array of solar cells encapsulated behind a sheet of glass. They have an aluminium frame for mounting the solar panels onto a roof and electrical cables for connecting the panels. The main ingredient of a solar panel is solar cells.

The Solar Cell

There are three main manufacturing steps to make solar panels.

First, you need to mine silicon and melt it into an ingot. The smelting process happens at a polysilicon factory. The factory will produce a mono-crystalline solar cell or a poly-crystalline solar cell.

The second step is to slice the silicon into thin wafers. This happens at a wafering plant.

The third step is to convert the solar wafers into solar cells. This happens at a solar cell factory.

A solar panel factory buys solar cells from the cell factory to make solar panels. The solar cells have a stated power rating. A solar cell measuring 160mm square could output 6.5 Watts. Manufacturing a standard solar panel requires 60 cells. 60 x 6.5W cells will produce a 390W solar panel.

Connecting The Solar Cells

A solar cell has a positive face and a negative back. The Voltage of a silicon solar cell is 0.5 V. This Voltage is very low. The way to increase the Voltage is to connect the solar cells together in series. To do this we need to connect the front of one cell to the back of its neighbouring cell. This is a series connection.

Connecting is by soldering copper ribbons. The front of one cell is connected to the back of the next cell. Soldering is by a tabber-stringer machine. The tabber-stringer is the most expensive machine on a solar panel production line. It is handling very delicate wafers to make solar panels. The output of the tabber-stringer machine is a single column of cells.

The Lay Up

The next step of the factory is to gather six columns of cells from the tabber-stringer machine and arrange them on a sheet of glass. An encapsulant layer then protects the cells.

A second encapsulant layer protects the back of the cells along with a back sheet. The back sheet will insulate and protect the delicate solar cells.

The lay-up process concludes with testing the solar panels. The testing is in an electroluminescence machine. This ensures there are no cracked solar cells inside the solar panel.

Removal of cracked or damaged cells is a manual process. Final testing is performed on the panels.

Lamination is required to make solar panels

The next step is to laminate the solar panel. This stage of the manufacturing process melts and encapsulants and hermetically seals the solar panel. The laminating process happens in a solar panel laminating machine.

The lamination is a batch process taking four solar panels at a time. It takes around 20 minutes to laminate the panels at a temperature of around 160°C. The lamination is a very important stage of the solar panel manufacturing process and it is key in determining the longevity of the solar panel.

Visual Inspection

As the solar panels exit the laminator machine an operator visually inspects each solar panel laminate. They are looking for any bubbles, imperfections, or dead insects or flies inside the encapsulated solar panel.

In a solar panel factory, you will see that there are lots of large insect killers everywhere to make sure bugs don’t end up preserved inside a solar panel. The tiniest contamination will mean the solar panel is defective.

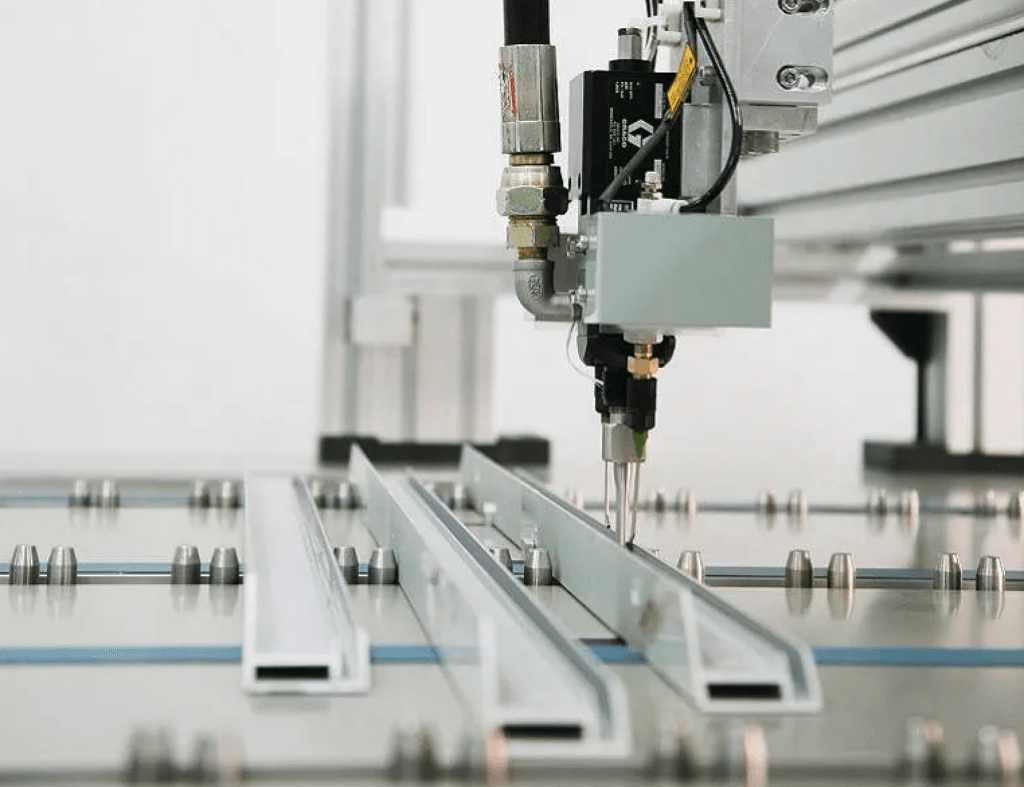

Framing makes solar panels rigid

The next stage is to frame the solar panel. The solar panel factory usually procures pre-cut aluminium frames. Most frames are 35mm high with a groove to hold the glass in place.

The machine applying the silicon and fixing the glass is a robot.

Junction Box

A junction box is fitted to the back side of the framed solar panel. The purpose of the junction box is to terminate the encapsulated, series-connected solar cells into a single cable pair of positive and negative.

Testing is the final step to make solar panels ready for use

The finished solar panel is tested for power output. The factory needs to check that a solar panel labelled 390 Watt will generate 390W in standard testing conditions.

Testing and a final inspection is the last manufacturing step. The solar panels are carefully stacked on pallets and wrapped to be ready for safe delivery.

There is only one solar panel factory in Australia. Most solar panel factories are located in China.